CO2 fire extinguishing system is recognized as one of the most effective and commonly used automatic fire extinguishing systems in many industrial environments. Specifically, CO2 possesses several advantageous properties:

- Electrically non-conductive: This makes it safe for use around sensitive electronics and electrical equipment.

- No residue upon evaporation: This eliminates the need for extensive cleanup after discharge, minimizing downtime and damage to equipment.

- Heavier than air: This allows the gas to blanket the fire and displace oxygen, effectively smothering the flames.

- Stable at high temperatures: CO2 does not decompose under the high temperatures encountered in fire conditions, ensuring its effectiveness.

- Relatively low cost: Both the equipment and the CO2 agent itself are generally more affordable than some other fire suppression systems.

The primary mechanism of CO2 fire extinguishing systems is oxygen reduction level in air. CO2 displaces oxygen in the vicinity of the fire, reducing its concentration below the level needed for combustion (typically below 15%).

In addition, the rapid discharge of CO2 causes a significant temperature drop in the affected area, further hindering combustion. While this cooling effect plays a supporting role, oxygen reduction remains the main extinguishing mechanism.

The health risk associated with carbon dioxide extinguishing systems is notable. At the concentrations needed to extinguish fires, CO2 becomes deadly even with brief exposure. This lethality stems from a severe lack of oxygen in the blood, triggered by a condition called hypercapnia.

However, the risk of exposure to carbon dioxide resulting from CO2 system discharge can be effectively managed.

When considering a CO2 extinguishing system, understanding the inherent risk to human life is paramount. These systems are strictly unsuitable for environments with permanent or regular human occupancy.

Properties of CO2 for Fire Extinguishing:

- Colorless and odorless at room temperature and pressure

- Non-conductive

- Non-corrosive and does not generate harmful chemicals near flames

- Readily available and relatively inexpensive

- Leaves no residue upon discharge

- Typically stored in 67-liter cylinders for automatic fire extinguishing applications

Usage of the CO2 system

CO2 is suitable for extinguishing Class A, B, and C fires but it cannot be used for Class D fires or materials that burn while producing oxygen, such as nitrocellulose and gunpowder.

This system is specifically used in industrial environments where one (or more) of the following applies:

- Normally, no person is permanently present in the area.

- In areas such as control rooms, server rooms, archive rooms, and other spaces where people are permanently present, the use of a Clean Agent gas fire extinguishing system such as IG or halocarbons is recommended.

- The presence of electrical equipment makes the use of a non-conductive material essential.

- Other extinguishing agents such as water, powder, or foam can damage equipment and materials or are expensive to clean up.

- The equipment needs to be protected using a Local Application system.

Some industrial areas where CO2 systems can be used include:

- Battery rooms

- Flammable liquid storage areas

- Cable ducts and trenches

- Cable trays

- Electrical rooms (such as switchgear rooms, cable galleries, etc.)

- Transformers

- Generators

- Flammable liquid storage rooms and enclosures

- Printing machines

- Rolling mills

- Hydraulic systems

- Marine applications

safety

Exposure to high concentrations of CO2 gas (which is typically required for fire suppression) can have extremely harmful effects on the human body and can even be fatal. At high concentrations, this gas causes suffocation. Additionally, it creates a white fog in the area that limits visibility and makes it difficult to evacuate.

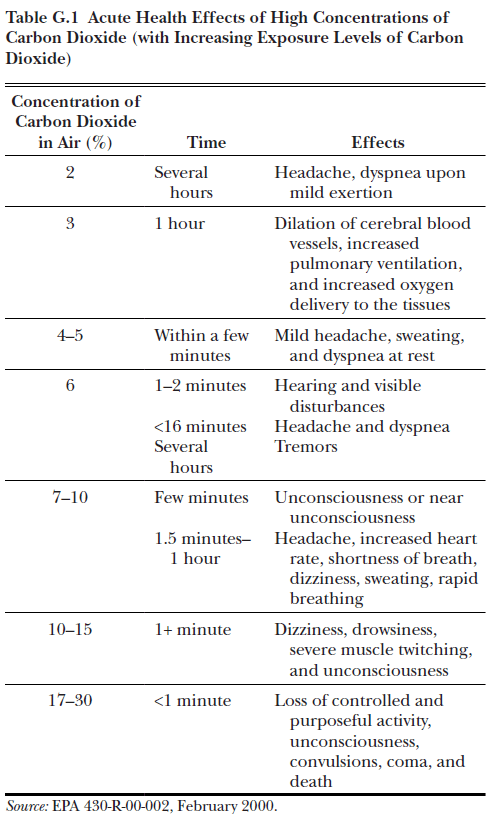

The figure below, taken from Appendix G of NFPA 12, shows the effects of CO2 on human health. It can be seen that long duration exposure to a 2% concentration of CO2 in air can cause headaches and shortness of breath during mild physical activity. a few minutes exposure to 4-5% of this gas causes mild headache and shortness of breath.

Exposure for a few minutes to 7-10% of this gas can cause blurred vision, tinnitus, headache, increased heart rate, rapid breathing, etc.

Exposure to concentrations greater than 10% by volume in air can cause symptoms such as blurred vision, tinnitus, and tremors, and personnel may lose consciousness within minutes. In concentrations greater than 20% by volume, there is a risk of death.

If a CO2 system is used, its safety aspects must be considered, and necessary training must be provided to employees and anyone who may be exposed to this gas. Without training, inexperienced personnel may not be able to think clearly and may take inappropriate action if they are suddenly exposed to relatively low concentrations of CO2.

Here are some additional safety considerations:

- Warning signs and alarms should be installed to alert people to the presence of CO2 gas.

- Emergency evacuation procedures should be in place and regularly practiced.

- Personnel should be trained on the hazards of CO2 gas and how to use personal protective equipment.

- Regular maintenance and inspection of the CO2 system should be carried out to ensure its proper functioning.

Equipment needed in the CO2 system to increase safety

1. Safety Signs:

According to NFPA 12, when using a CO2 fire suppression system, warning signs must be installed in a clear and visible manner:

- Inside rooms

- At the entrance to the space

- In adjacent spaces where CO2 gas can be discharged

- At the entrance to the cylinder storage room

- Near the keys or manual activation valves of the fire suppression system

The figure below shows the warning signs required by NFPA 12:

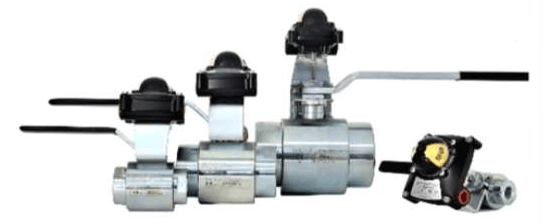

2. Lockout Valve:

According to the NFPA 12 standard, each CO2 system must be equipped with a mechanical lockout valve which can be locked in the closed position to prevent flow of carbon dioxide to the protected area. This valve must has an open or closed status indicator.

3. Pneumatic time delay system:

According to the NFPA 12 standard, a pneumatic delay system must be included in CO2 system. This system creates a delay of approximately 30 seconds before CO2 gas enters the area, allowing for the evacuation of personnel. It is important to note that while delay systems are common in other fire suppression systems, the NFPA 12 standard specifically requires pneumatic delay systems for CO2 systems.

4. Pneumatic Siren:

Each CO2 system must have a pneumatic siren installed to alert personnel of system activation before the gas enters the area. An example of this device is shown in the figure below.

5. Odorizer:

Since CO2 is an odorless gas, an odorizer must be included in each system. The odorizer’s function is to add a scent to the discharged gas to alert personnel of the CO2 gas discharge, in addition to visual and auditory alarms.

It is important to note that this device is usually installed at the beginning of the piping system or on the manifold of the CO2 system and adds a substance to the passing gas that gives it an odor.

Types of CO2 systems

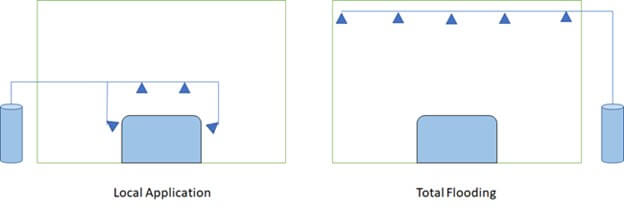

CO2 fire extinguishing systems primarily utilize one of two methods: Total Flooding or Local Application. The choice between these methods typically depends on the nature and characteristics of the protected area. In both cases, the carbon dioxide tank or cylinders connect to a fixed network of piping and discharge nozzles, directing the CO2 gas to the protected area. Notably, both systems offer manual and automatic activation options.

In total flooding systems, CO2 gas is discharged into an enclosed space and fills the entire space after a specific period of time known as the discharge time. In this method, the quantity of CO2 required is determined based on various factors such as the fire classification, type and severity of the fire hazard.

It is important to note that in total flooding systems, CO2 gas must remain in the space at the desired concentration to sufficiently cool the burning materials and prevent re-ignition. Therefore, the space must be sufficiently enclosed to maintain the concentration of the extinguishing agent for a minimum hold time.

The local application method is used in areas where there is no enclosed space around the protected area, or the dimensions of the enclosed space are much larger than the area to be protected. Therefore, in this method, the protected area may be located inside an enclosed space or in an open space. However, in open spaces, the layout of the discharge nozzles must be such that the discharge of carbon dioxide gas is not affected by air currents or wind.

The Local Application method is used in areas where there is no enclosed space around the protected area or the dimensions of the enclosed space are much larger than the area to be protected Therefore, in this method, the area under protection may be inside the closed space or in the open space Of course, in open spaces, the arrangement of discharge nozzles should be such that the discharge of carbon dioxide gas is not affected by air flow or wind

High Pressure and Low Pressure Systems

Based on the CO2 storage method in the tank, CO2 systems can be classified into two main categories: High pressure and Low pressure systems.

- In High Pressure systems, carbon dioxide gas is stored in high-pressure cylinders with an ambient temperature range of -18°C to 54°C. The density of the CO2 gas in these cylinders is between 600 and 680 kg/m3, and at a temperature of 21°C, the pressure inside the cylinder reaches approximately 58.6 bar.

- Low Pressure systems utilize tanks with a controlled temperature of -18°C to store the CO2 gas. At this temperature, the pressure within the storage tanks is 300psi (pounds per square inch).

For large systems (usually with a capacity exceeding 2000 kg of CO2 gas), the initial cost of a Low Pressure system is lower compared to a High Pressure system.

Technical specifications of the CO2 fire extinguishing system:

| Chemical name | Carbon Dioxide |

| Chemical formula | CO2 |

| Reference standard | NFPA 12 |

| Density at 0°C and 0.101 MPa | Mpa 1.98 kg/m3 |

| Density relative to air | 1.5 |

| Critical temperature | 31°C |

| Cylinder capacity | 67.5 liters |

| Cylinder diameter (Approximate) | 267mm |

| Cylinder height (approximately) | 1600mm |

| Weight of filled cylinder | 100~120 kg |

Design concentration (volume percentage): | |

| Dry electrical hazard | 50% |

| Paper archive | 65% |

| Design concentration (volume percentage) Fire caused by flammable and combustible liquids (according to NFPA 12 standard) | |

| Gasoline, diesel fuel, butane | 34% |

| Ethanol | 43% |

| Hydrogen | 75% |