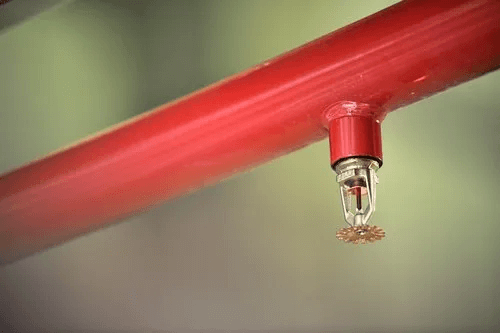

A sprinkler fire extinguishing system is one of the most common water-based fire extinguishing systems used in residential, commercial, and industrial buildings. Each sprinkler system typically consists of a network of pipes connected to a stable water supply, such as a pump and water tank, and at the end connected to sprinkler heads. Sprinklers are usually installed near the ceiling or on the side walls. In the event of a fire, the thermal element (usually a glass bulb) on the sprinkler detect heat and activates, automatically discharges water onto the fire. The sprinkler system can operate independently, without an electrical fire alarm system, to suppress the fire.

Components of each sprinkler

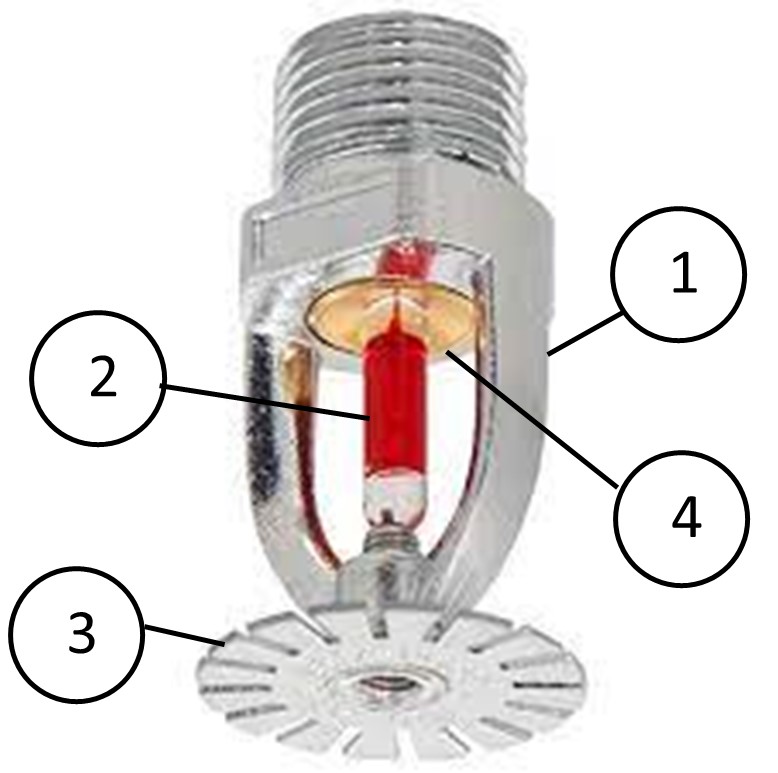

The figure below shows an automatic sprinkler. It consists of four main parts:

- Body (1): The main housing of the sprinkler.

- Heat-sensitive element (2): Usually a glass bulb filled with a temperature-sensitive liquid.

- Deflector (3): A metal plate that shapes the water spray pattern.

- Cap (4): Covers the orifice and prevents water from flowing until the sprinkler is activated.

In the event of a fire, heat from the fire causes the liquid in the glass bulb to expand and break the bulb. This releases the cap and allows water to flow through the sprinkler. The water hits the deflector and is sprayed in a specific pattern to cover the area below the sprinkler.

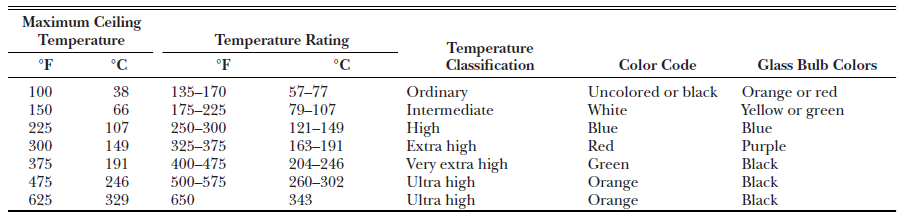

Sprinklers are available with different temperature ratings. The color of the liquid in the glass bulb indicates the sprinkler’s operating temperature. The figure below shows some sprinklers with different temperature ratings.

In an automatic sprinkler system, only the sprinklers that are exposed to heat will open during a fire. The rest of the sprinklers will remain closed. This helps to minimize potential water damage to areas that are not affected by the fire.

Types of sprinklers

The technology behind sprinkler construction has undergone significant changes since its inception. Prior to the 1950s, sprinklers were built to discharge roughly 40 to 60 percent of the water downwards, with the remaining amount discharged upwards. It was believed that this method would aid in cooling the ceiling and improve fire suppression. These sprinklers are currently known as “old-style” or “conventional” sprinklers, and their use is now limited to specific situations.

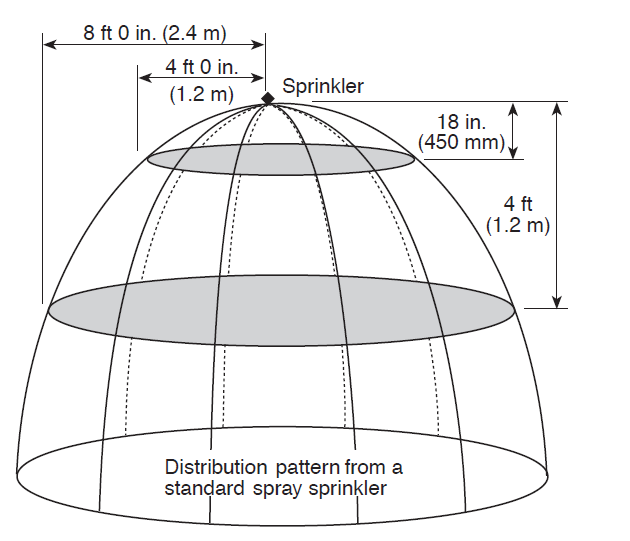

Spray sprinklers are currently the most popular choice, designed to replace older conventional models. Unlike their conventional sprinklers, spray sprinklers direct all water downwards onto the fire zone. The image displays the spray pattern following NFPA 13 standards. Beyond widely-used spray sprinklers, other options exist, including residential sprinklers specifically designed for residential areas, ESFR and CMSA sprinklers mostely used in storage areas, and open sprinklers.

Each type of sprinkler has its own unique set of features that make it suitable for different applications. Some of the most important features to consider when choosing a sprinkler include

Sprinkler operating temperature:

Sprinkler operating temperature is the temperature at which the sprinkler’s thermal element is expected to activate and discharge water.

According to the NFPA 13 standard, standard installations usually call for Ordinary (57-77°C) or Intermediate (79-107°C) temperature class sprinklers, as shown in the first two rows of the table below.

However, in general, the sprinkler operating temperature is determined based on the maximum ceiling temperature of the building (Maximum Ceiling Temperature column).

The table below shows the sprinkler operating temperature based on the maximum ceiling temperature of the building.

Temperature sensitivity:

Regarding the temperature sensitivity feature of sprinklers, one can mention quick response (Quick Response) and standard response (Standard Response) sprinklers. Quick response sprinklers have a higher performance speed than standard response sprinklers. But it should be noted that the performance speed of sprinklers depends on many factors such as ceiling height, sprinkler distance to ceiling, sprinkler arrangement, ambient temperature, etc. and the use of quick response sprinklers does not necessarily mean quick activation of sprinklers in any situation.

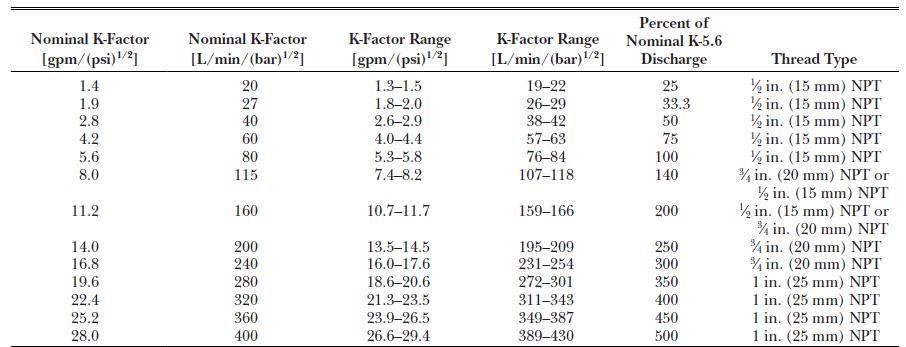

K factor:

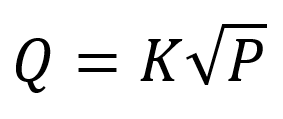

Different sprinklers are manufactured with different K-factors. The K-factor is a coefficient that depends on the size and characteristics of the sprinkler orifice. In fact, the larger the K-factor, the more water will be discharged from the sprinkler at a constant pressure. The relationship between flow rate, pressure, and K-factor is expressed as follows:

Installation Orientation

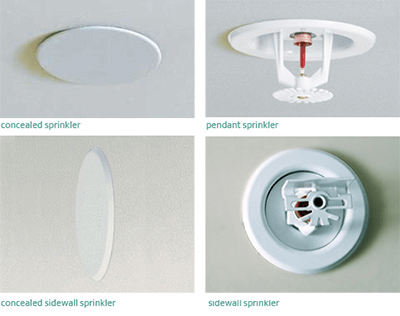

Sprinklers can be classified into three types based on their installation method and orientation: Pendent sprinklers, Upright sprinklers and Sidewall sprinklers.

The type of sprinkler to be used depends on the architectural features of the building and the limitations of the sprinkler installation in the area. It is important to note that the installation direction is a characteristic of the sprinkler and must be considered during installation. For example, a pendent sprinkler must be installed pointing downwards and cannot be used facing upwards or at other angles.

It is important to note that all of the above mentioned sprinklers discharge water downwards, and only their installation direction differs. In addition to the above sprinklers, there are other types that are designed to help preserve the aesthetics of a building. These include concealed sprinklers and recessed sprinklers.

Special working conditions:

Some specific conditions require the use of sprinklers with special features. These sprinklers include corrosion-resistant sprinklers, dry sprinklers, and others.

Types of sprinkler systems

The most common sprinkler systems are:

- Wet Pipe Sprinkler System

- Dry Pipe Sprinkler System

- Pre-action System

- Deluge System

In the following, each of these systems will be briefly explained

Wet sprinkler system

The wet pipe sprinkler system is the most common type of sprinkler system. In this system, the sprinklers are automatic, meaning that each sprinkler has a heat element that activates when exposed to heat and water is discharged in the area. Additionally, in this system, there is water in the entire piping network and up to the back of the sprinkler. These features ensure that water is discharged from the sprinkler as soon as it is activated.

Where there are no restrictions on the use of the wet system (such as low ambient temperature and the possibility of freezing), this system should be considered as the first choice.

Some of the equipment used in the pipe sprinkler system are:

- Alarm Check Valve

- Water Motor Alarm Gong

- Flow control valves, such as butterfly valves, gate valves, ball valves, etc.

- Water Flow Switch

- Pressure Switch

- Relief Valve

- Automatic air drain valve (Vent Valve)

Dry pipe sprinkler system

Dry pipe sprinkler systems are used in places where the ambient temperature may be below 4 degrees Celsius and there is a risk of water freezing. In this system, similar to the wet pipe sprinkler system, the sprinklers are automatic or closed. However, unlike the wet pipe sprinkler system, there is no water up to the sprinklers and instead, the piping network is filled with pressurized air or nitrogen. In this system, water and air are separated by a proportional valve called a dry pipe valve. a sample of dry pipe valve is shown in the figure opposite.

When a fire occurs and the sprinklers are activated, the air inside the pipe starts to evacuate first. Over a relatively short period of time, the air pressure inside the pipes decreases and the pressure difference created between the air and water causes the Dry Pipe Valve to open and the water inside the pipes to flow. Finally, water is discharged from the sprinklers onto the fire area.

It can be seen that in the dry system, there is a delay in the evacuation of air, the opening of the Dry Pipe Valve, and the arrival of water to the sprinklers, while in the wet pipe system, water is discharged into the area as soon as the sprinklers open. This delay is the biggest weakness of the dry system compared to the wet system, and to minimize it, the requirements of NFPA 13 standard in this regard should be fully considered during the design.

Pre-action sprinkler system

In a pre-action system, the task of fire detection is assigned to both the sprinklers themselves and an auxiliary fire detection system. The auxiliary fire detection system is mostly considered to be a smoke detector, but other types of fire alarm systems can also be used.

Depending on the type of interaction between the auxiliary fire detection system and the sprinklers with the Preaction valve, this system is divided into three categories:

- Single Interlock System: In this system, the pre-action valve is activated only by the activation of the auxiliary fire detection system, and the opening of the sprinklers has no effect on it. This system operates faster than the dry pipe system and can be used as a substitute for the dry pipe system where there is a risk of freezing (as a solution to reduce delay time).

- Non-Interlock System: In this system, the pre-action valve is activated by the activation of the auxiliary fire detection system or by the opening of the sprinklers. In other words, the activation of either of them causes the valve to open. This system is more sensitive than the single interlock system. This system can also be used as a substitute for the dry pipe system.

- Double Interlock System: In this system, both the auxiliary fire detection system and the sprinklers must be activated simultaneously for the pre-action valve to open. In this system, the delay in the time it takes for water to reach the area is exactly the same as in the dry pipe system, and the requirements of NFPA 13 standard must be considered to reduce the time it takes for water to reach the area