Halocarbon clean agent fire suppression systems are mostly known by their trade names, such as FM200 or Novec 1230. Halocarbons, along with inert gases (IGs), are a subset of clean agents that are designed according to the NFPA 2001 standard and can be used in rooms where people are normally present.

One of the main advantages of halocarbon fire suppression systems over IG fire suppression systems is that they require less space for cylinder storage and have a lower cylinder working pressure. This has made the use of FM200, Novec, and other halocarbon fire suppression systems popular in many urban applications where there is limited space for cylinders or where the cost of providing additional space is prohibitive.

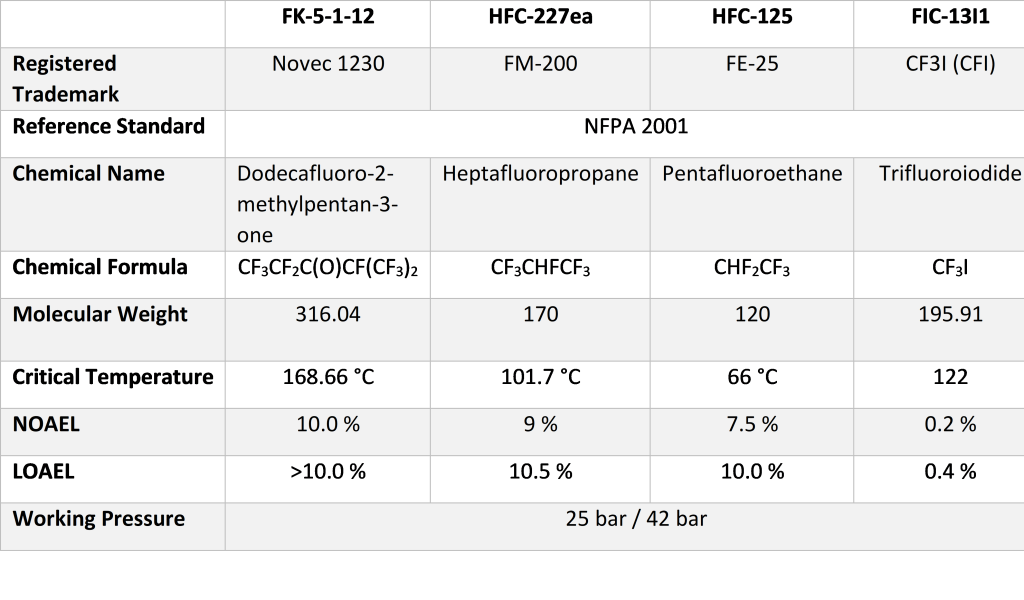

The following table lists the most important halocarbon clean agents approved by the NFPA 2001 standard, along with their trade names.

| NFPA 2001 Standard Title | Brands | Chemical name |

| FK-5-1-12 | Novec 1230 | Dodecafluoro-2- methylpentan-3-one |

| HFC-227ea | FM-200 | Heptafluoropropane |

| HFC-125 | FE-25 | Pentafluoroethane |

| FIC-13I1 | CF3I (CFI) | Trifluoroiodide |

Halocarbons extinguish fires through a combination of chemical and mechanical mechanisms. Most halocarbons, such as FM200 and Novec 1230, use various chemical properties like heat of vaporization, heat capacity, and energy absorption through chemical decomposition (breaking of chlorine and fluorine bonds) to extract heat from the area around the flame, resulting in flame temperature reduction and extinguishment of the fire.

Halocarbons have slightly different properties and characteristics. However, the following properties can be considered for all halocarbons:

- All halocarbons are non-conductive of electricity.

- All halocarbons leave no residue after discharge.

- All halocarbons are stored in pressurized cylinders as liquids.

- In all halocarbon fire suppression systems (except HFC-23), nitrogen gas is used to pressurize and push the gas through the piping network.

- Most halocarbons can be used as a substitute for Halon 1301 with similar hardware.

- Halocarbons decompose when exposed to flame and high heat and produce some chemicals (such as HF).

- In fire suppression systems, halocarbons are stored in cylinders with different capacities from 5 liters to 240 liters.

- Ozone Depletion Potential (ODP) in all halocarbons is zero or close to zero.

- Compared to other similar fire suppression systems, much less space is required to store halocarbon cylinders.

- Halocarbon fire suppression systems are used in almost all cases as Total Flooding.

- If the standard requirements are met, in fire suppression applications, humans can be exposed to most halocarbons (except FIC-13I1) for a maximum of 5 minutes.

When selecting gas systems for fire protection, cost, the possibility of complete sealing of the area to keep the gas for the standard time, and the space required to store the cylinders should be considered as influencing factors.

Use cases of FM200 and Novec 1230 systems

Halocarbon fire suppression systems, including FM200 and Novec 1230, can be used to extinguish Class A, Class B, and Class C fires. However, they are not suitable for extinguishing Class D fires or materials that produce oxygen when they burn, such as nitrocellulose and gunpowder.

These systems are particularly useful in environments where one or more of the following conditions apply:

- People are present in the area either normally or permanently, and there is a concern for personal safety.

- The presence of electrical equipment necessitates the use of a non-conductive agent.

- Other extinguishing agents such as water, powder, or foam would damage the equipment or materials present, or their cleanup would be costly.

- There is insufficient space for storing the large number of cylinders required in other similar fire suppression systems (such as IG), or doing so would be prohibitively expensive.

Some industrial areas where FM200 and Novec 1230 halocarbon fire suppression systems can be used include:

- Control rooms and engineering rooms

- Computer rooms

- Server rooms and data centers

- Telecommunication facilitie

- Museums

- Archive rooms

- Libraries

- Electrical rooms (such as switchgear rooms, cable galleries, etc.)

NFPA 2001 Exposure Limits for Halocarbon Fire Suppression Systems

According to NFPA 2001, human exposure to halocarbon fire suppression agents for up to 5 minutes is not considered hazardous if the system is designed in accordance with the standard and the extinguishing agent concentration does not exceed the specified limits.

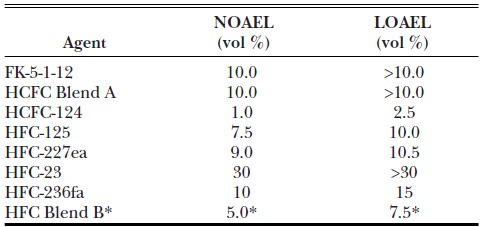

NFPA 2001 defines two exposure limits based on the concentration of the extinguishing agent in the air and the potential hazards:

- NOAEL (No Observed Adverse Effect Level): The maximum concentration of the extinguishing agent in the air at which no adverse physiological or toxicological effects have been observed.

LOAEL (Lowest Observable Adverse Effect Level): The minimum concentration of the extinguishing agent in the air at which an adverse physiological or toxicological effect has been observed.

The following table shows the NOAEL and LOAEL limits for halocarbon fire suppression systems according to NFPA 2001:

For example, according to the above table, when designing an FM200 fire suppression system, it is important to ensure that the volume concentration of the gas in the air does not exceed 10.5%. This number is 10% for Novec gas.

Technical specifications of halocarbon fire extinguishing system