Deluge Valve is one of the most widely used equipment for fire extinguishing systems in various industries. Deluge valve is designed to open quickly and allow a large volume of water to flow through in the event of a fire. In fact, the main feature of the Deluge valve is its very fast operation (from closed to fully open condition). This valve is used in various types of water and foam fire extinguishing systems.

How Deluge Valves Work

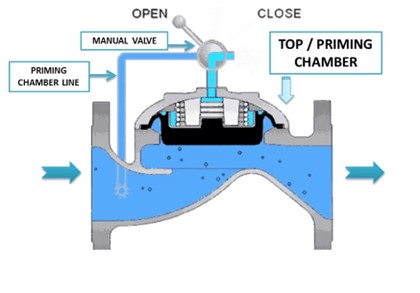

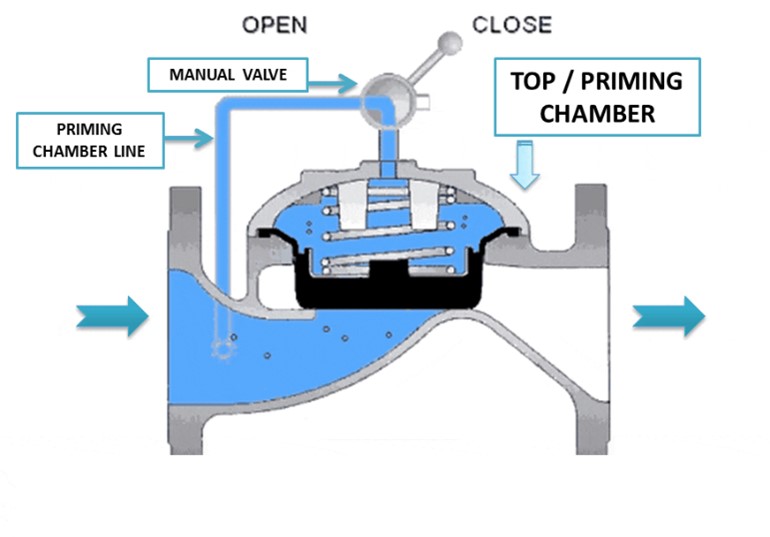

The general operation of deluge valves is similar to each other, with some minor differences. Inside these valves there is a chamber (Priming Chamber) to which the main line water is transferred through a side pipe (Trim or Priming Chamber Line). This chamber is connected to a diaphragm that is responsible for opening and closing the valve. The design of the chamber and diaphragm is such that if there is water pressure behind it, the valve closes, and if the water pressure is removed from inside it in any way, the valve opens. Therefore, the deluge valve can be activated by emptying the tank water manually, electrically or hydraulically. The following figures show the closed and open state of a deluge valve.

Water Spray Nozzle System

One of the main applications of Deluge valves is their use in fixed water spray systems. In a fire water spray system, water is sprayed onto equipment or a specific area using special spray nozzles.

Unlike sprinkler systems, the nozzles in this system are open and do not have a thermal element. Therefore, the task of fire detection is assigned to an auxiliary detection system, which can be electrical or other types of fire alarm systems. In this system, the Deluge valve is responsible for opening the piping path and delivering water flow to the nozzles. This system can operate automatically, manually, or a combination of both.

Water spray systems are generally designed and installed according to NFPA 15 standard.

Applications of Nozzle Spray System

Water spray systems can be effectively used for fire extinguishing, equipment cooling, surrounding cooling, fire prevention and fire control in various industries. Some areas where the water spray system can be used for fire protection include:

- Extinguishing fires caused by ordinary combustibles such as paper, wood, cloth, etc. with high speed performance

- Protecting some electrical equipment including transformers, rotating machines (such as pumps and compressors, turbines)

- Controlling fires in storage tanks containing liquid or gas fuels

- Controlling fires in rotary equipment such as pumps and compressors

- Cable tunnels containing cables or electrical conduits

- Conveyor belt

- Cooling process equipment in various industries, steel structures and their surroundings

To effectively use water systems, especially water spray systems, the nature of the protected materials and the physical and chemical properties of the materials present in the area must be fully considered. The requirements of NFPA 15 standard must also be fully considered.

Types of Spray Nozzles

Some types of spray nozzles include hollow cone, full cone, and flat discharge nozzles. Each of these nozzles has its own unique characteristics, including spray angle, K-factor, and water velocity.

In selecting spray nozzles, it is necessary to consider factors such as the characteristics of the protected area, the purpose of the system (fire suppression, cooling of adjacent areas, fire extinguishing, etc.), and environmental factors such as strong winds.

In addition to the various spray angles, droplet sizes, and velocities, spray nozzles are available in different discharge patterns such as hollow cone, full cone, and flat fan. Some even have a spiral path for deeper water penetration.

Some nozzles are also designed to create a swirling motion in the water stream with a spiral path. This increases the depth of water penetration.

Medium velocity water spray nozzles are typically used for fire protection of flammable liquids with low flash points and water-miscible liquids (polar solvents, alcohols, etc.) in small sizes. In contrast, high velocity water spray systems are typically used to extinguish fires involving medium and heavy flammable oils and similar materials with flash points above 65 degrees Celsius (e.g., transformers, lubricating oil tanks, etc.).

Other applications of high velocity nozzles include protection of equipment with complex physical shapes (e.g., rotating machines).