The use of dry chemical powder is more common in portable fire extinguishers, but automatic powder fire extinguishing systems are also used to protect against various types of fires.

Dry chemical powder is a solid substance (usually based on sodium bicarbonate and potassium or monoammonium phosphate) that is ground into very fine particles. It behaves like a fluid when moving through piping and discharged in the fire area. In this system, the powder is stored in pressurized cylinders. In the event of a fire, the powder is propelled by the external pressure generated by nitrogen gas into the piping network and discharged through special nozzles onto the fire area.

There are different types of dry chemical powders, which are usually based on sodium bicarbonate and potassium or monoammonium phosphate. The different properties of the different types of powders mean that some powders are more effective in certain conditions. For example, the use of potassium-based powders is not recommended for protection against Class A fires (fires of ordinary materials such as wood and paper) or some types of powders have been developed and approved by various manufacturers for protection against fires caused by active metals (Class D).

Dry chemical powders extinguish fires by acting on the flame through chemical mechanisms (disrupting chain reactions).

Automatic dry chemical powder fire extinguishing systems (unlike portable dry chemical powder fire extinguishers, which are used in accordance with NFPA 10) are designed and installed in accordance with NFPA 17 or BS EN 12416.

Equipment of Dry Chemical Powder Fire Extinguishing System

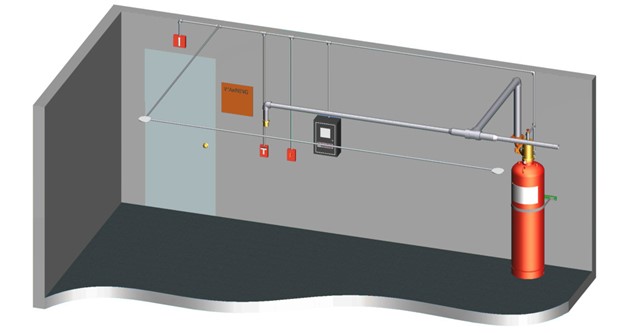

Typically, each automatic powder fire extinguishing system includes the following equipment:

- Cylinders and powder storage equipment: This includes the set of powder storage cylinders, ABC powder (or other types of powder, depending on the type of fire), discharge valve, manual discharge lever, solenoid valve and other related equipment.

- Piping and powder distribution components: This includes pipes and fittings, pipe supports, discharge nozzles and other items and equipment that are responsible for transferring the powder from the cylinder to the protected area.

- Control panel: The control panel monitors system components and triggers powder release upon fire detection. This is responsible for monitoring electrical actuators, detectors, warning devices, cylinder pressure, etc. All electrical and electronic devices must be connected to the control panel for their operation.

- Fire detection and warning equipment: This includes fire detection equipment and audible and visual warning equipment.

- Additional components: This includes pressure gauges, pressure switches, vent valves, check valves, hoses and other items and equipment that will be required for the correct and complete installation of the dry chemical powder fire extinguishing system.

Important Considerations for Using Dry Chemical Powder Fire Extinguishing Systems

Dry chemical powder fire extinguishing systems are primarily used for flammable and combustible liquids and gases, as well as other types of surface fires. However, careful consideration is necessary for combustible solids, deep-seated fires, and special cases due to specific powder requirements.

It should also be noted that the powder discharged after the fire extinguishing operation needs to be cleaned up, and this can cause damage to sensitive electrical and electronic equipment. In addition, some powders may react chemically with metals such as iron and aluminum and have corrosive properties. Therefore, before selecting and using this system to protect highly sensitive equipment, careful evaluations should be carried out and the environment and equipment should be thoroughly cleaned after discharge.

Discharging large amounts of powder in enclosed spaces can pose respiratory risks and reduce visibility. Evacuate the area before activating the automatic powder system.